Wallboard Installation and Maintenance INDeX Wallboard 22

INDeX Contact Centre Modules Page 99

Installation & Maintenance 38HBK00001SCM - Issue 11 (05/01)

Periodic Maintenance and Inspection

Cleaning Display Screen

Time periods between cleaning depend upon local conditions and are at the

discretion of the operator. This routine cleaning can be carried out in the normal

way using a damp and/or dry cloth.

Note: This screen is specially coated to reduce reflections and although this coating is very

durable misuse or incorrect cleaning procedures can damage it.

LED Illumination Test Inspection

The purpose of this test is to ensure no LED fails to illuminate and should be

checked annually.

Remove the left-hand end cheek and carefully slide out the logic control board so

that the dip-switches are accessible. Set switch 8 to ON, inspect the LED display

that will run blocks of Green, Red and Yellow across the display. Look for any LEDs

that fail to illuminate.

Return switch 8 to the OFF position to stop this test.

LED Matrix Scanning Inspection

The purpose of this inspection is to ensure the LED matrix is being scanned

correctly. Remove the left-hand end cheek and carefully slide out the logic control

board so that the dip-switches are accessible.

Set switch 7 to ON, Yellow diagonal stripes will run across the display. Check that

these stripes are straight and that Yellow is the only colour displayed. Having

completed this visual inspection return switch 7 to OFF and ensure that all switch

settings comply with system requirements for baud rate and wallboard network

address number. See Section D for dip-switch details.

Serial Connection & Dip-Switch Details

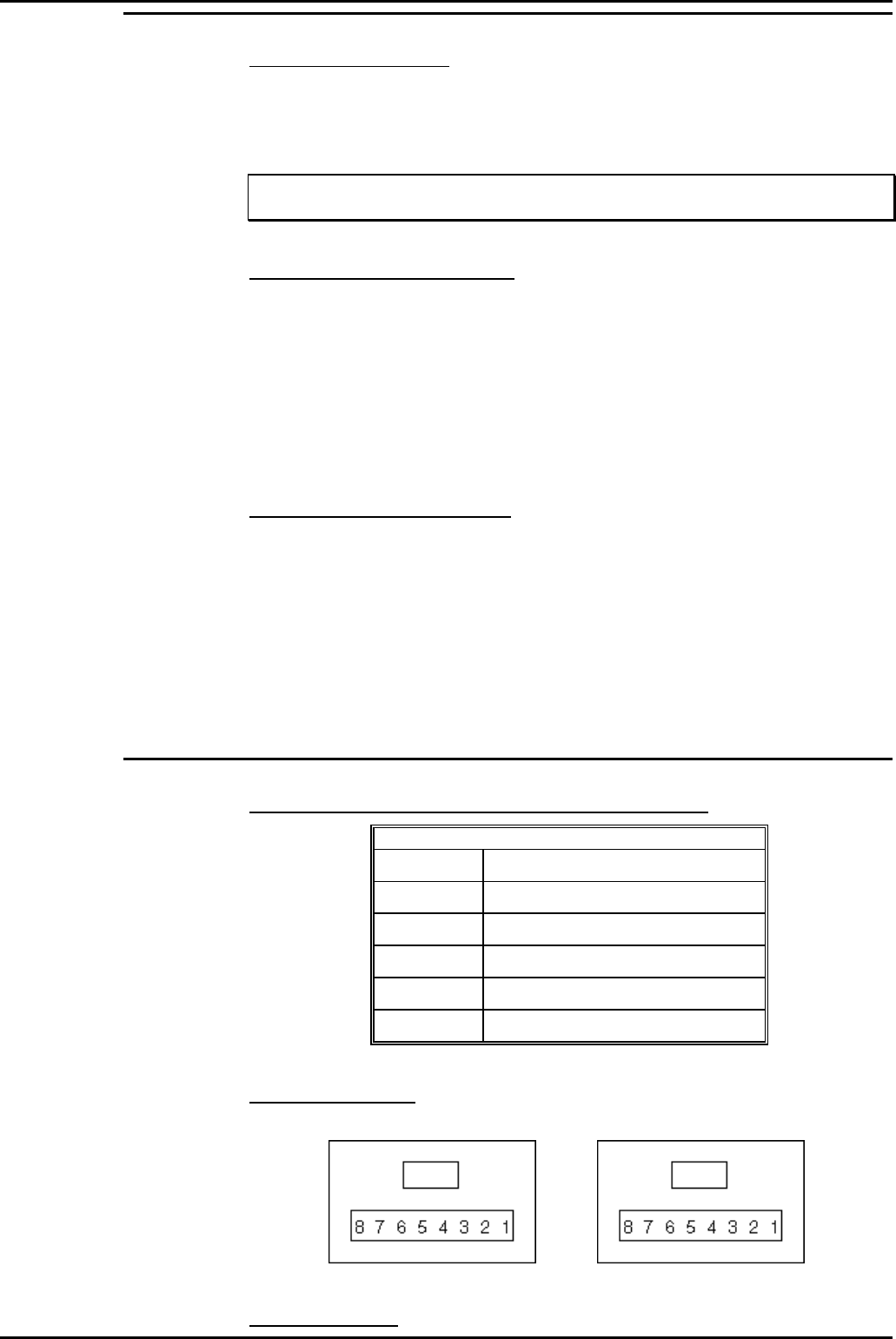

Wallboard Terminal Box RJ45 Connector Pin Out Details

Pin

2 Signal Ground

3 Sign Rx+ Input

4 Sign Tx+ Output

5 Sign Tx- Output

6 Sign Rx- Input

7–

Pin out Connections

Wallboard x RJ45 Socket Wallboard x+1 RJ45 Socket

Pins from 2 to 7 should be connected identically from all RJ45 boxes to all others.

Dip-Switch Details