29

Machine Start Delay — An option to delay the start of

the machine is also available. This parameter is useful in keep-

ing multiple machines from starting at the same time in case of

a power failure. The parameter has a factory default of

1 minute. This parameter also has a role in the timing for a

chilled water flow switch alarm. The flow switch status is not

checked until the delay time has elapsed.

To configure this option with the Touch Pilot display:

To configure this option with the Navigator display:

Circuit/Compressor Staging and Loading —

The AquaForce

®

30XW chillers employ one compressor per

circuit. As a result, circuit and compressor staging are the

same. The control has several control option parameters to load

the compressors. The circuit/compressor start can be config-

ured as well as the loading of each circuit/compressor.

CIRCUIT/COMPRESSOR STAGING — The control can be

configured to decide which circuit/compressor starts first, by

configuring Lead/Lag Circuit Select (Staged Loading

Sequence, LLCS). Three options for this variable are allowed:

Automatic Lead-Lag, Circuit A Leads or Circuit B Leads. The

factory default is Automatic Lead-Lag.

The automatic lead-lag function determines which circuit/

compressor starts. When enabled, the control will determine

which circuit/compressor starts to even the wear of the com-

pressor. The compressor wear factor (combination of starts and

run hours) is used to determine which compressor starts.

Compressor Wear Factor = (Compressor Starts) + 0.1 (Com-

pressor Run Hours)

The circuit/compressor with the lowest compressor wear

factor is the circuit that starts first.

If starting a particular circuit/compressor first is desired, that

can also be configured with the same variable.

To configure this option with the Touch Pilot display:

To configure this option with the Navigator display:

CIRCUIT/COMPRESSOR LOADING — The control can

be configured to stage the circuit/compressors. The Loading

Sequence Select (Circuit Loading Sequence, LOAD) setting

determines how the control will perform loading. The configu-

ration can be set to Equal or Staged.

Equal Loading

— With Equal loading, the circuit which starts

first will maintain the minimum stage of capacity with the slide

valve fully unloaded. When additional capacity is required, the

next circuit with the lowest compressor wear factor is started

with its slide valve at minimum position. As additional capaci-

ty is required, the slide valve for a circuit will be adjusted in

approximately 5% increments to match capacity requirements.

The control will alternate between circuits to maintain the same

percentage of capacity on each circuit.

Staged Loading

— If staged loading is selected, the circuit

which starts first will gradually load its slide valve to match

capacity requirements until the circuit is fully loaded. Once the

circuit is fully loaded and additional capacity is required, the

control will start an additional circuit fully unloaded. The con-

trol will gradually unload the circuit which was fully loaded to

match capacity requirements.

To configure this option with the Touch Pilot™ display:

To configure this option with the Navigator™ display:

Minimum Load Control — Minimum Load Control

can be a factory-installed option or a field-installed accessory.

If installed, and its operation is desired, the Minimum Load

Control must be enabled. Once enabled, the valve will be oper-

ational only during the first stage of cooling.

To configure this option with the Touch Pilot display:

A power cycle is required for the values to take effect.

To configure this option with the Navigator display:

A power cycle is required for the values to take effect.

Dual Chiller Control — The dual chiller routine is

available for the control of two units installed in series or paral-

lel supplying chilled fluid on a common loop. One chiller must

be configured as the master chiller, the other as the slave chill-

er. An additional leaving fluid temperature thermistor (dual

chiller LWT) must be installed in the common chilled water

piping as described in the Installation Instructions for both the

master and slave chillers. See the Field Wiring section in the

30XW Installation Instructions for dual chiller LWT sensor

control wiring.

The control algorithm relies on several parameters that must

be field configured for operation. Both chillers must be on the

same Carrier Comfort Network

®

bus with different addresses.

On both chillers, Master/Slave Select (Master/Slave Select,

MSSL) must be enabled. The water piping arrangement, Chill-

ers in Series (Chiller in Series, SERI), must be configured.

The master chiller must be programmed with the Slave Chiller

Address (Slave Address, SLVA). Additional optional pro-

gramming parameters may be configured to meet application

requirements.

Lead/Lag Balance Select (Lead Lag Select, LLBL) deter-

mines which chiller is the lead machine. The options are Al-

ways Lead, Lag if Fail, and Runtime Select. Under Runtime

Select control, the lead chiller will change based on the time in-

crement selected in the Lead/Lag Balance Delta configuration

(Lead/Lag Balance Data, LLBD). If the run hour difference

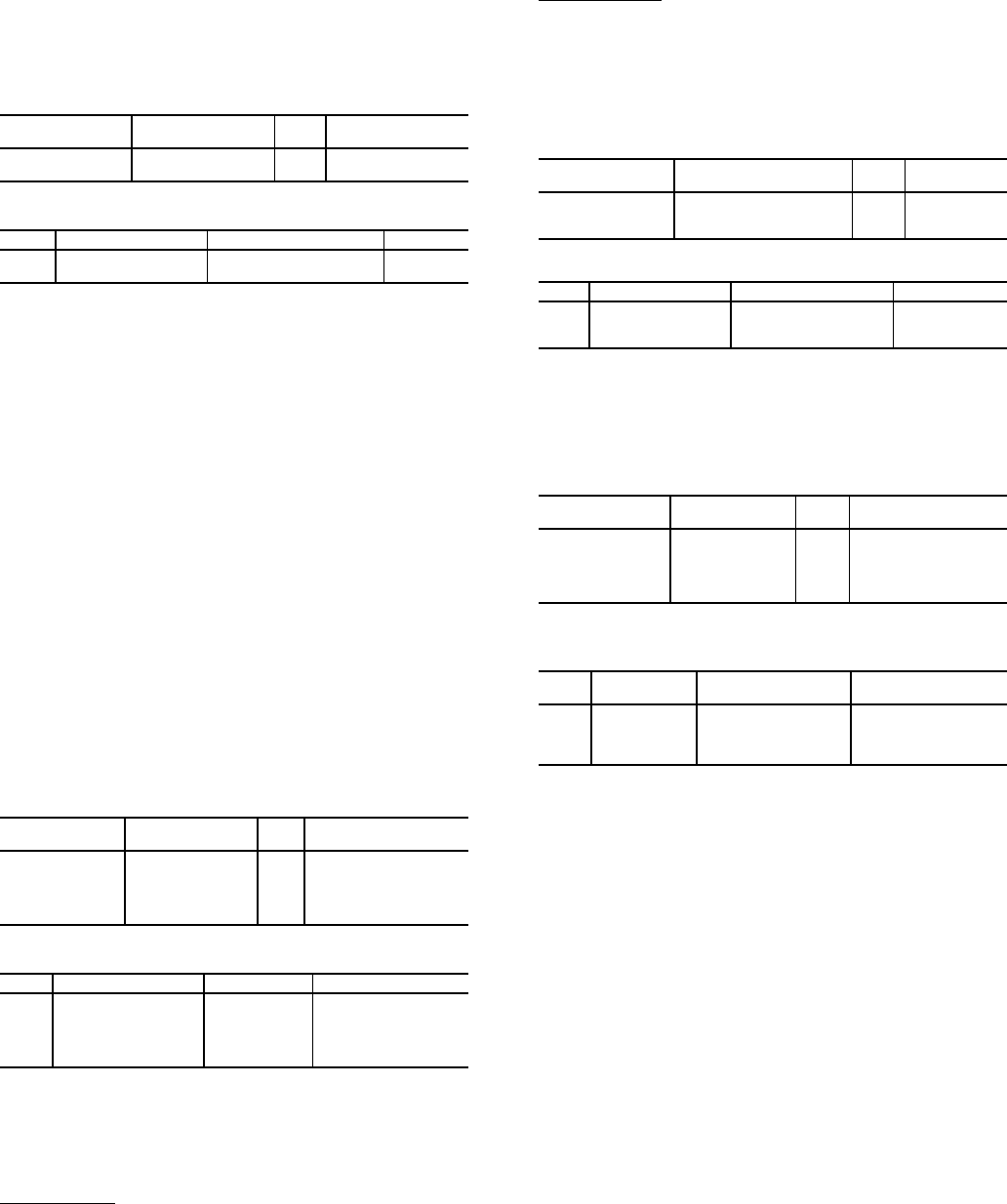

DISPLAY NAME PATH

LINE

NO.

VALUE

Unit Off to

On Delay

Main Menu

Config USER

6 Default = 1 Minute

ITEM ITEM EXPANSION PATH VALUE

DELY Minutes Off Time Configuration OPTN

Default =

1 Minute

DISPLAY NAME PATH

LINE

NO.

VALUE

Circuit Loading

Sequence

Main Menu

Config USER

1

0 (Automatic Lead-lag)

1 (Circuit A Leads)

2 (Circuit B Leads)

Default = 0

(Automatic Lead-lag)

ITEM ITEM EXPANSION PATH VALUE

LLCS

Lead/Lag

Circuit Select

Configuration

OPTN

Range: Automatic,

Cir A Leads,

Cir B Leads,

Cir C Leads

Default – Automatic

DISPLAY NAME PATH

LINE

NO.

VALUE

Staged Loading

Sequence

Main

Menu Config USER

4

Default = No

No (Equal)

Yes (Staged)

ITEM ITEM EXPANSION PATH VALUE

LOAD

Loading Sequence

Select

Configuration OPTN

Default = Equal

Equal

Staged

DISPLAY NAME PATH

LINE

NO.

VALUE

Hot Gas

Bypass Select

Main

Menu Service

FACTORY

14

Default = No

No (No Minimum

Load Control)

Yes (Minimum Load

Control Installed)

ITEM

ITEM

EXPANSION

PATH VALUE

HGBP

Hot Gas

Bypass Select

Configuration UNIT

No = No Minimum

Load Control

Yes = Minimum Load

Control Installed