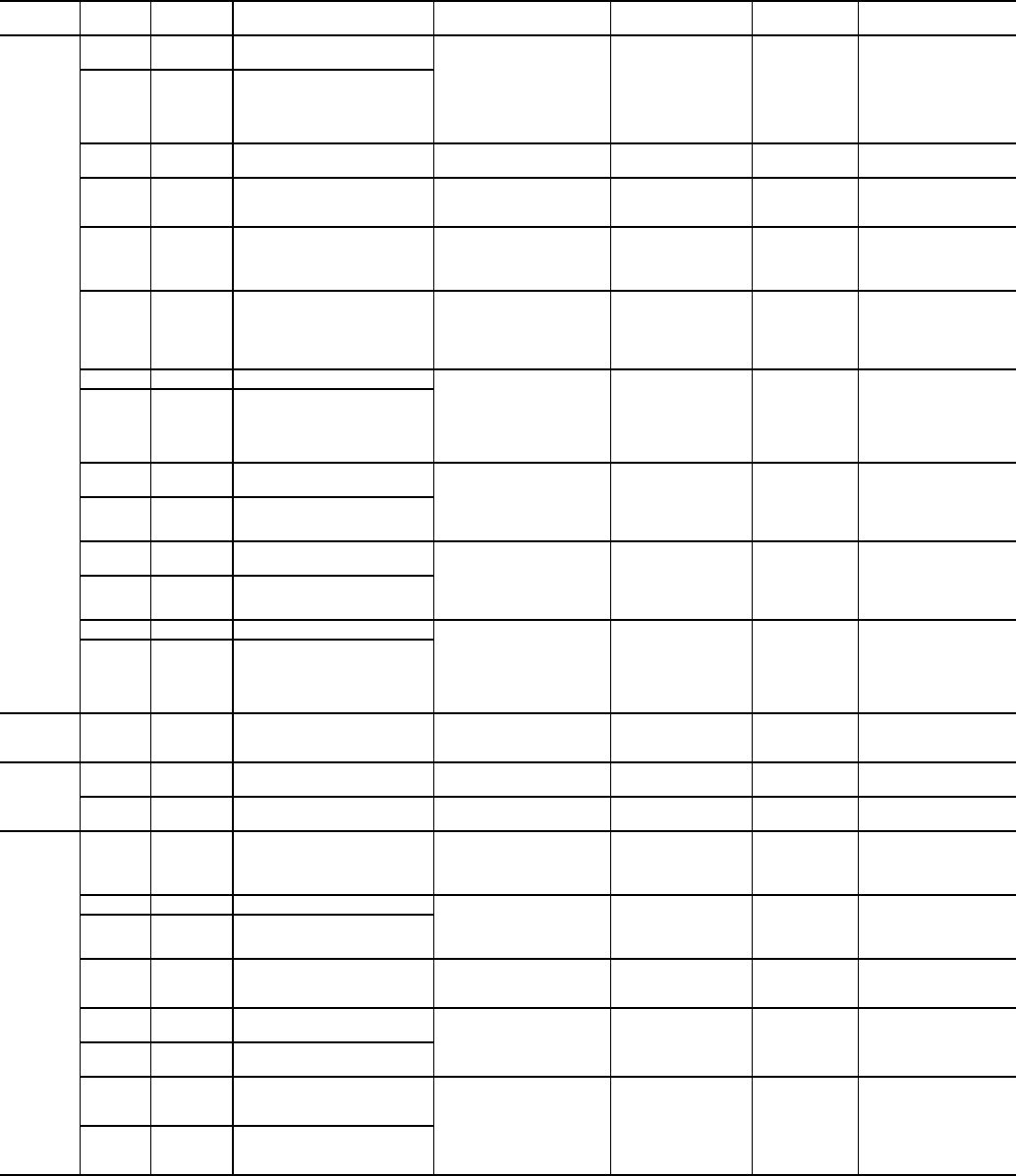

71

Table 49 — Alarm Codes (cont)

LEGEND

PREFIX

CODE

SUFFIX

CODE

ALARM

NUMBER

ALARM DESCRIPTION REASON FOR ALARM

ACTION TAKEN

BY CONTROL

RESET

TYPE

PROBABLE CAUSE

P 11 77 Circuit A Low Suction

Superheat

EXV<5% and either the

suction superheat is less

than the set point by at

least 5 F or the suction

temperature is greater

than MOP set point for

more than 5 minutes

Circuit shut down Manual Faulty transducer,

faulty wiring, faulty

thermistor, faulty EXV,

or incorrect

configuration

12 78 Circuit B Low Suction

Superheat

14 80 Interlock Failure Lockout Switch Closed Unit shut down or

not allowed to start

Automatic Lockout Switch Closed

on EMM board

28 81 Electrical Box Thermostat

Failure/Reverse Rotation

External pump interlock

open

Unit shut down or

not allowed to start

Automatic External pump off.

Faulty jumper wiring

when channel not used

29 82 Loss of communication with

System Manager

Loss of communication

with an external control

device for more than

2 minutes

Unit change to

stand-alone

operation

Automatic Faulty communication

wiring, no power

supply to the external

controller

30 83 Master/Slave communication

Failure

Communication between

the master and slave

machines lost

Unit change to

stand-alone

operation

Automatic Faulty communication

wiring, no power or

control power to the

main base board of

either module

67 84 Circuit A Low Oil Pressure Oil pressure and suction

pressure differential is

less than the set point

Circuit shut down Automatic, first

occurrence in

24 hours;

manual if

multiple alarms

within 24 hours

Plugged oil filter, faulty

oil transducer, oil check

valve stuck, plugged oil

strainer

68 85 Circuit B Low Oil Pressure

70 87 Circuit A Max Oil Filter Differ-

ential Pressure

Difference between dis-

charge pressure and oil

pressure is greater than

50 psi for more than

30 seconds

Circuit shut down Manual Plugged oil filter,

closed oil valve, bad oil

solenoid, oil check

valve stuck, faulty oil

pressure transducer

71 88 Circuit B Max Oil Filter Differ-

ential Pressure

84 90 Circuit A High Oil Filter Drop

Pressure

Difference between dis-

charge pressure and oil

pressure is greater than

30 psi for more than

5 minutes

Alert generated Manual Plugged oil filter

85 91 Circuit B High Oil Filter Drop

Pressure

75 93 Circuit A Low Oil Level Oil level switch open Circuit shut down or

not allowed to start

Automatic, first

occurrence in

24 hours;

manual if

multiple alarms

within 24 hours

Low oil level, faulty

switch, wiring error,

failed CPM board, oil

solenoid stuck open

76 94 Circuit B Low Oil Level

MC nn 96 Master chiller configuration

error Number 01 to nn

Wrong or incompatible

configuration data

Unit not allowed to

start in Master-slave

control

Automatic Configuration error

FC n0 97 No factory configuration No Configuration Unit not allowed to

start

Automatic Configuration error

nn 98 Illegal factory configuration

Number 01 to 04

Wrong or incompatible

configuration data

Unit not allowed to

start

Automatic Configuration error

P 31 99 Unit is in CCN emergency

stop

Emergency stop com-

mand has been received

Unit shut down or

not allowed to start

Automatic Carrier Comfort

Network

®

Emergency

Stop command

received

32 100 Cooler pump #1 fault Pump interlock status

does not match pump

status

Unit shuts down, if

available, another

pump will start

Manual Faulty contacts, wiring

error or low control

voltage. Configuration

error.

33 101 Cooler pump #2 fault

15 102 Condenser Flow Switch

Failure

— None Manual Configuration error,

faulty wiring or external

pump off

34 103 Circuit A Reclaim Operation

Failure

— None Manual Configuration error

35 104 Circuit B Reclaim Operation

Failure

37 105 Circuit A — High condensing

temperature out of compres-

sor envelope

Multiple capacity over-

rides due to high

saturated discharge

temperature

Circuit shut down Automatic Low or restricted

condenser water flow.

Fouled condenser

tubes.

38 106 Circuit B — High condensing

temperature out of compres-

sor envelope

CCN — Carrier Comfort Network

®

MLV — Minimum Load Valve

CPM — Compressor Protection Module MOP — Maximum Operating Pressure

EMM — Energy Management Module MTA — Must Trip Amps

EWT — Entering Water Temperature SST — Saturated Suction Temperature

EXV — Electronic Expansion Valve UL — Underwriters Laboratories

HPS — High Pressure Switch