FX

3G

/FX

3U

/FX

3UC

PLC User's Manual - Positioning Control Edition

Built-in Positioning Functions

13 Troubleshooting

13.1 LED Indicator Lamp Check

B - 171

A

Common Items

B

Built-in

Positioning

Functions

Apx.

Example

Connection

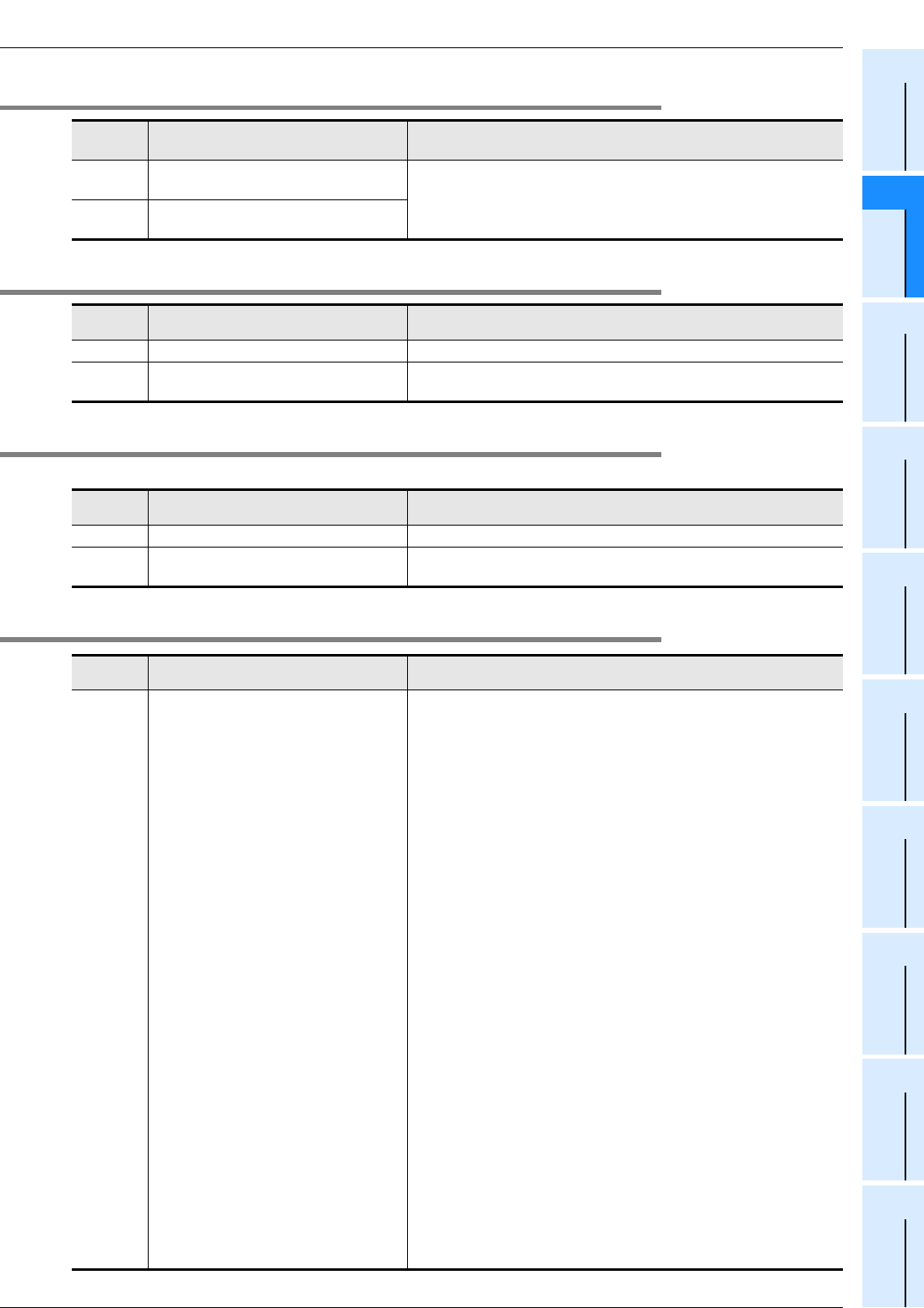

13.1.2 RUN Indicator Lamp (Statuses: ON, OFF) [FX3G/FX3U/FX3UC]

13.1.3 BATT Indicator Lamp (Statuses: ON, OFF) [FX3U/FX3UC]

13.1.4 ALM Indicator Lamp (Statuses: ON, OFF) [FX3G]

This LED is valid when the optional battery is installed and the battery mode is selected using a parameter.

13.1.5 ERROR indicator lamp (Statuses: ON, flashing, OFF) [FX3G/FX3U/FX3UC]

Lamp

status

Status of PLC Troubleshooting

ON

The sequence program is being

executed.

The RUN indicator lamp indicates the operation status of the PLC.

Note that the RUN indicator lamp will go out depending on the status

of the ERROR indicator lamp (refer to Subsection 13.1.4).

OFF

Execution of the sequence program is

stopped.

Lamp

status

Status of PLC Troubleshooting

ON

The voltage of the battery is too low. Immediately replace the battery (refer to the manual of the PLC).

OFF

The battery supplies enough voltage as

specified by D8006.

The PLC has no problems.

Lamp

status

Status of PLC Troubleshooting

ON

The voltage of the battery is too low. Immediately replace the battery (refer to the manual of the PLC).

OFF

The battery supplies enough voltage as

specified by D8006.

The PLC has no problems.

Lamp

status

Status of PLC Troubleshooting

ON

A watchdog timer error may have

been detected, or the hardware of the

PLC may be damaged.

1) Stop the PLC, and then turn the power ON again. If the

ERROR (ERR) indicator lamp goes out, check to see if a

watchdog timer error has been detected, and take one of the

following measures.

- Review the program.

The maximum value of the scanning time (D8012) should

not be larger than the set value of the watchdog timer

(D8000).

- The interrupt input and the pulse catch input should not be

turned on and off too frequently during 1 scan time.

- The frequency of the pulse input to the high-speed counter

should not exceed the specified range (duty:50%)

- Add several WDT instructions.

Set several WDT instructions in the program so that the

watchdog timer can be reset several times during 1 scan

time.

- Change the set value of the watchdog timer.

Using the program, change the set value of the watchdog

timer (D8000) so that the set value of the watchdog timer

(D8000) can be larger than the maximum value of the

scanning time (D8012).

2) Remove the PLC, and put it on a workbench. Supply another

source of power to the PLC.

If the ERROR (ERR) indicator lamp does not light, the cause

of the problem may be noise. In this case, take the following

measures.

- Check the grounding line, and change the wiring route and

the installation place.

- Adopt a noise filter for the power supply line.

3) If measures 1) and 2) do not turn the ERROR indicator lamp

OFF, please contact the nearest

Mitsubishi Electric

distributor

office.