American Steel Design

Section 2

2-14

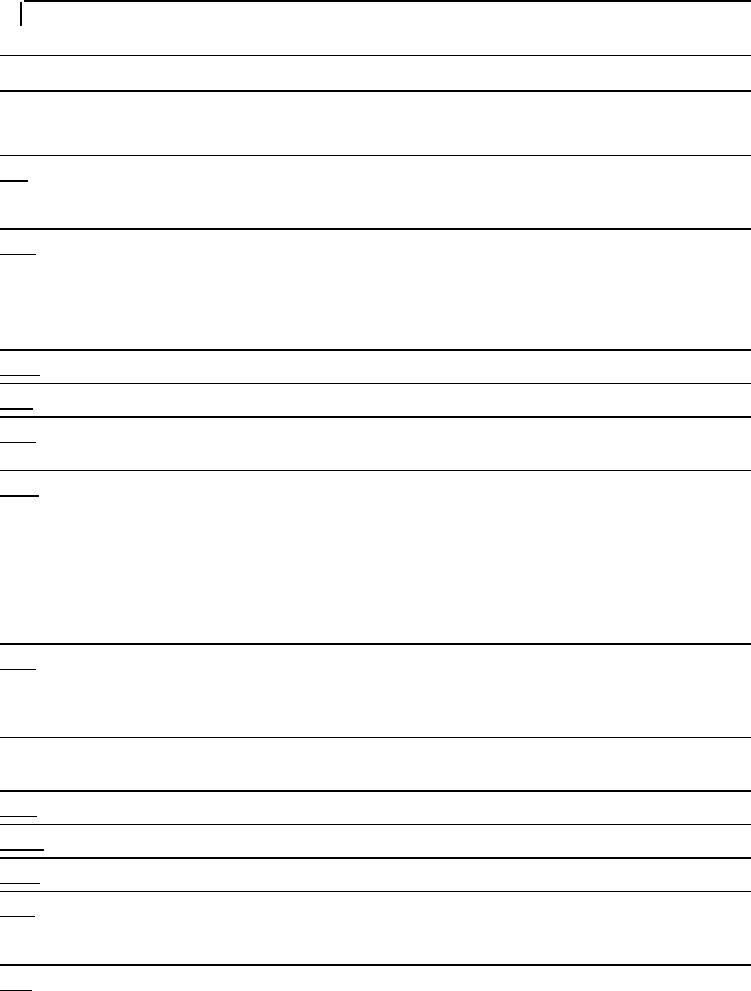

Table 2.1 - AISC Parameters

Parameter Default Description

Name Value

STIFF Member length or depth

of beam whichever is

greater

Spacing of stiffeners for plate girder design

TRACK 0.0

Controls the level of detail to which results

are reported.

0 = Minimum detail

1 = Intermediate detail level

2 = Maximum detail (see Figure2.1)

DMAX 1000 in. Maximum allowable depth.

DMIN 0.0 in. Minimum allowable depth.

RATIO 1.0 Permissible ratio of the actual to allowable

stresses.

WELD 1 for closed sections

2 for open sections

Weld type, as explained in section 2.12. A

value of 1 will mean welding is on one side

only except for wide-flange or tee sections,

where the web is always assumed to be

welded on both sides. A value of 2 will mean

welding on both sides. For closed sections

like pipe or tube, the welding will be on one

side only.

BEAM 1.0 0.0 = design at ends and those locations

specified by the SECTION command.

1.0 = design at ends and at every 1/12

th

point

along member length. (Default)

PROFILE None Used in member selection. See section

5.47.1 for details.

WMIN See Sect. 2.12 Minimum welding thickness.

WMAX See Sect. 2.12 Maximum welding thickness.

WSTR 0.4 x FYLD Allowable welding stress.

DFF None

(Mandatory for deflection

check)

"Deflection Length" / Maxm. allowable local

deflection

DJ1 Start Joint

of member

Joint No. denoting starting point for

calculation of "Deflection Length" (See Note

1)