American Steel Design

Section 2

2-84

The design method is the allowable stress method, using mainly

the rules stated in the AISC ASD 9

th

edition code. Only code

checking is currently available for castellated beams. Member

selection is not.

Design parameters:

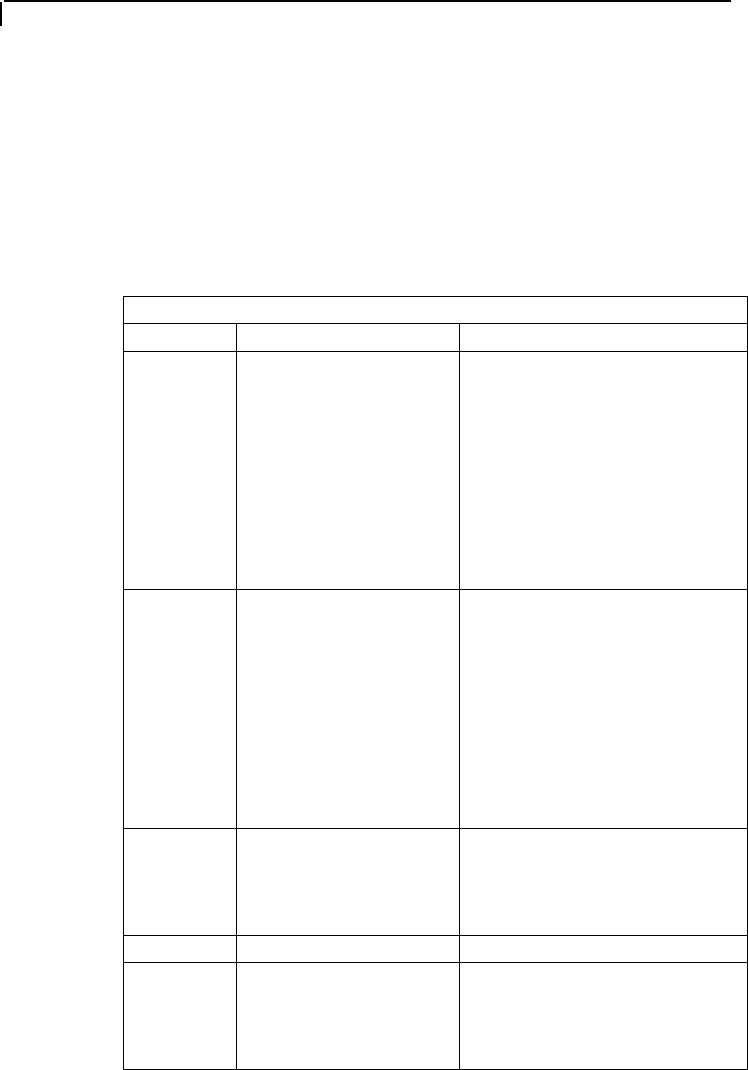

The following table contains a list of parameters and their default

values.

Table 2.7

Parameter Default Value Description

SOPEN 1.5e + b is the minimum

allowable value. Any

user-specified value

higher than or equal to

this minimum will be

used by the program.

“e” and “b” are as

described in the next

figure.

Distance from the start of the

member to the center of the first

hole.

EOPEN 1.5e + b is the minimum

allowable value. Any

user-specified value

higher than or equal to

this minimum will be

used by the program.

“e” and “b” are as

described in the next

figure.

Distance from the center of the

last hole to the end of the

member.

UNL Member length Unsupported length of

compression flange for

calculating allowable bending

stress.

FYLD 36 ksi Yield Stress of Steel

CB 1.0 Cb value used for computing

the allowable bending stress per

Chapter F of AISC

specifications.