American Steel Design

Section 2

2-36

2

6

50 10 1.75 8.6564 0.28389 11.46

0.772 9.87

33.38789 120 8.6564 120

cz

F

××

⎛⎞ ⎛⎞

=

+=

⎜⎟ ⎜⎟

⎝⎠ ⎝⎠

64375.03 psi

From this, calculated FCZ = 64.37.As this is larger than 0.55xF

Y

FCZ = 0.55xF

Y

= 19.8 ksi

Axial Compression:

Critical (kL/r)

y

= 1.0 x 120/1.5038 = 79.7978

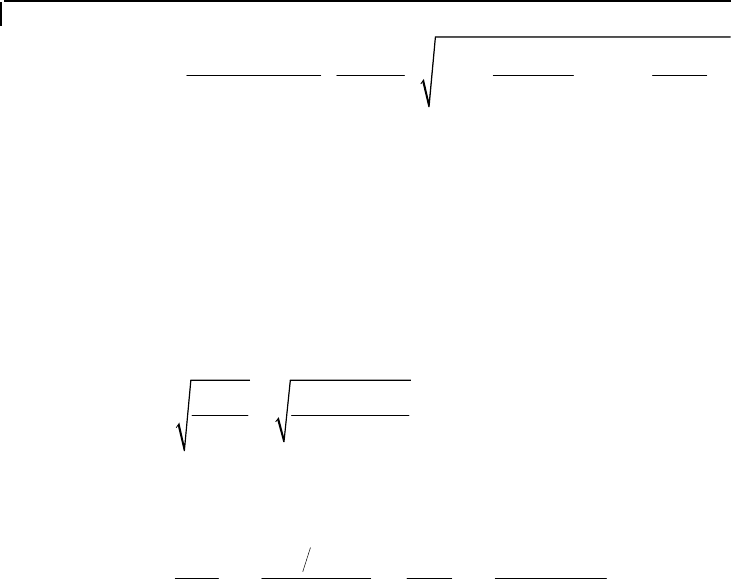

22

2 2 *29000

126.099

36

c

y

E

C

F

ππ

== =

As (kL/r)

y <

C

c

, the allowable axial stress in compression

()

()

2

2

22

79.79 36

36

1 1 13.58

. . 4 2.12 4 29000

yy

a

FKLrF

F

FS E

ππ

⎡⎤

⎡⎤

⎢⎥

=− =− =

⎢⎥

⎢⎥

⎢⎥

⎣⎦

⎣⎦

ksi

Shear:

Allowable shear stress as per gross section, F

v

= 0.33xF

Y

= 11.8

ksi

Actual Stress Calculation:

Actual stress (f

a

) = 25/7.65 = 3.26 ksi.

Actual bending stress = 56.5 x12/33.4 = 1.691616 x 12 = 20.29932

ksi

The critical moment occurs at the end node of the beam. So we use

the AASHTO equation 10.42 in section 10-36 to calculate the

design ratio.