American Steel Design

Section 2

2-38

Bending Minor Axis:

Allowable minor axis bending stress:

FTY = FTZ = 0.55 x F

Y

= 19.8 ksi

Bending Major Axis:

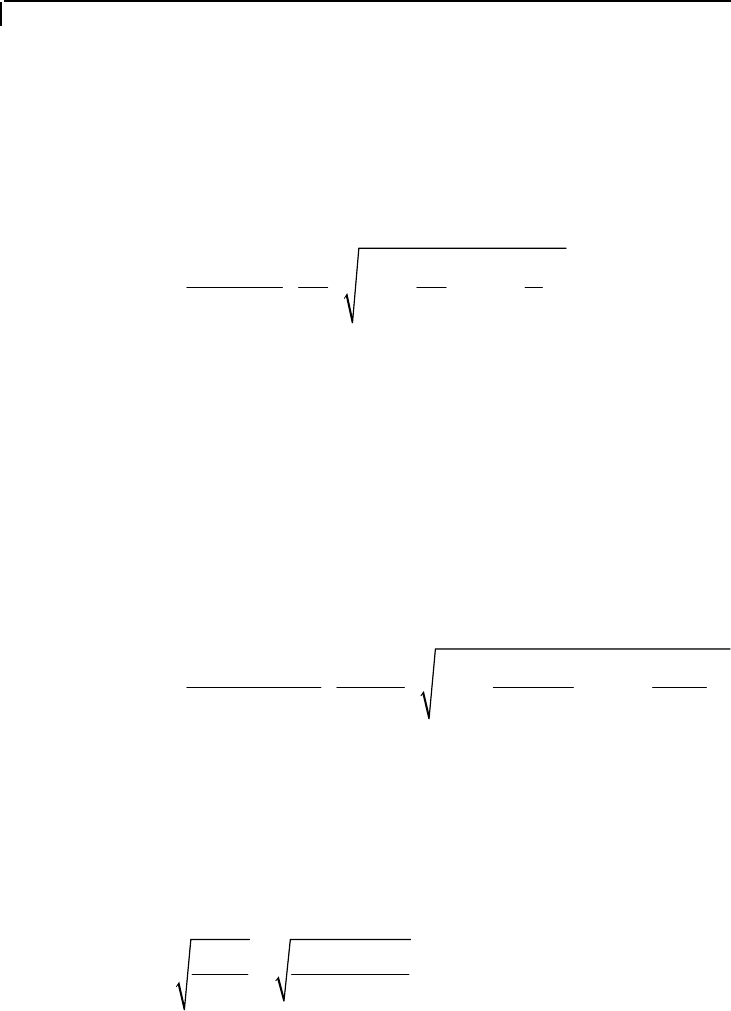

2

6

50 10

0.772 9.87 0.55

yc

b

cz y

xc yc

I

xC

Jd

FF

Sl I l

⎛⎞

⎛⎞

=+

⎜⎟

⎜⎟

⎝⎠

⎝⎠

≤

Where, C

b

= 1.75+ 1.05(M1/M2)+0.3x(M1/M2)

2

Here M1 = 39.44, M2 = 677.96 so C

b

= 1.69

S

zc

=Section modulus w.r.t. compression flange =204/(0.5X12.22)

= 33.38789 in

3

I

YC

= tb

3

/12 = 0.38 x 6.49

3

/12 = 8.6564 in

4

J = (2 x 6.49x0.38

3

+ (12.22 – 2x0.38)x0.23

3

)/3 = 0.28389 in

4

2

6

50 10 1.69 8.6564 0.28389 11.46

0.772 9.87

33.38789 60 8.6564 60

cz

F

××

⎛⎞ ⎛⎞

=

+=

⎜⎟ ⎜⎟

⎝⎠ ⎝⎠

227337.5 psi

Since FCZ is larger than 0.55xF

Y,

FCZ = 0.55xF

Y

= 19.8 ksi

Axial Compression:

Critical (KL/r)

y

= 1.0 x 60/1.503 = 39.92

22

2 2 *29000

126.099

36

c

y

E

C

F

ππ

== =