American Steel Design

Section 2

2-28

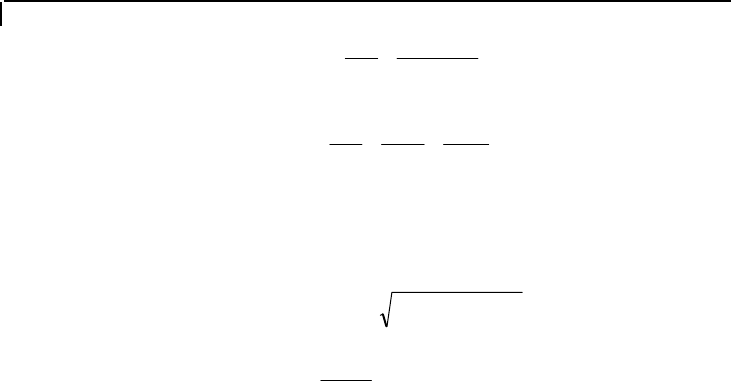

Vertical stress,

Fv

VY

AX

CV MX

JW

=+

×

Direct stress,

Fd

FX

AX

MZ

SZ

MY

SY

=+ +

**

* The moments MY and MZ are taken as absolute values, which may result

in some conservative results for asymmetrical sections like angle, tee and

channel.

Combined force

FFF

comb h v d

=

22

+ + F

2

Weld thickness

=

F

F

comb

w

where F

w

= Allowable weld stress, default value is 0.4 FYLD

(Table 2.1).

The thickness t is rounded up to the nearest 1/16th of an inch and

all the stresses are recalculated. The tabulated output prints the

latter stresses. If the parameter TRACK is set to 1.0, the output

will include the weld properties. The program does not calculate

the minimum weld thickness as needed by some codes, but checks

only against the minimum thickness as provided by the user (or

1/16th inch if not provided).

When the TRUSS qualifier is used with SELECT WELD

command, the program will design the welds required for truss

angle and double angle members that are attached to gusset plates.

The program reports the number of welds (two for single angles,

four for double angles), and the length required for each weld. The

thickness of the weld is taken as 1/4 inch (6 mm) for members up

to 1/4 inch (6 mm) thick, and 1/16 inch (1.5 mm) less than the

angle thickness for members greater than 1/4 inch (6 mm) thick.

Minimum weld length is taken as four times weld thickness.