o

a

a

o

o

o

o

o

o

o

o

a

o

o

o

t

O

I

o

o

e

a

o

o

o

c

o

o

I

o

o

a

o

o

a

o

a

o

o

O

o

O

o

o

lf

you

desire

to remove

the component

l€ads,

use

a

J.5 Y

ol

tess

pencil

type

iron.

Straigtrten-the

teads

on

me

oacK

side

of

the board;

then

when

the

sotder

melts,

gently

puil

the

sotdered

tead

through

the

hote.

A

desoldering

tool

should

be

used

to

-remove

the

old

solder.

Use

a

desoldering

toot

that

has

a

low

build-up

of

static

charge,

such

as

SiMerstat

Soldapullt

desolder-

ing

tool,

when

unsoldering

integrated

circuiis

or

transis_

tors.

Replacing

the

Square

pin

tor

the

Multi-pin

Connsctors

It

is

important

not

to

damage

or

disturb

the

ferrule

when

removing

the

old

stub

of

a

broken

pin.

Tne

ter_

rule

is

pressed

into

the circuit

board

and

provides

a

base

for

soldering

the

pin

connector.

lf

the

broken

stub

is

long

enough,

grasp

it

with

a

pair

of

needle

nose

pliers,

appty

treatl

wiih

a small

sold-

ering

iron,

to

the

pin

base

of

ine

ferrute

and

pull

the old

pin.

out.

(Ihe

pin

is

pressed

into

th€

terruie

so

a

firm

pull

is

r€quired

to

pult

it out.)

lf

the

broken

stub.is-too

short

to

grasp

with

pliers,

use

a small

dowel

(0.029

inch

in

diameter;

clamped

in

a

vise

to.push

the

pin

out

of

the

ferrule

after

the solder

has

melted.

The

old

ferrule

can

be

cleaned

by

reheating

socket

and

placing

a

sharp

object

such

as

a

toothpicklr

small

dowel lnto

the

hote.

A

O.Ogl

inch

driil

mounted

in

a

pin

vise

may

also

be

used

to

ream

the

solder

out ol

the

old

ferrule.

-

Ur."

a

pair

of

diagonal

cutters

to remove

the ferrule

from

the new

pin;

then

insert

the

pin

into

the otd

ferrule

and

solder

the

pin

to both

sides

oi

the

ferrute.

.

lf

it-is,-necessary.to

bend

the

new

pin,

grasp

the

base

of

the

pin

with

needle_nose

pliirs

and

bend

against

the

pressure

of

ths

pliErs

to avoid

breaking

the

board

around

the

ferrule,

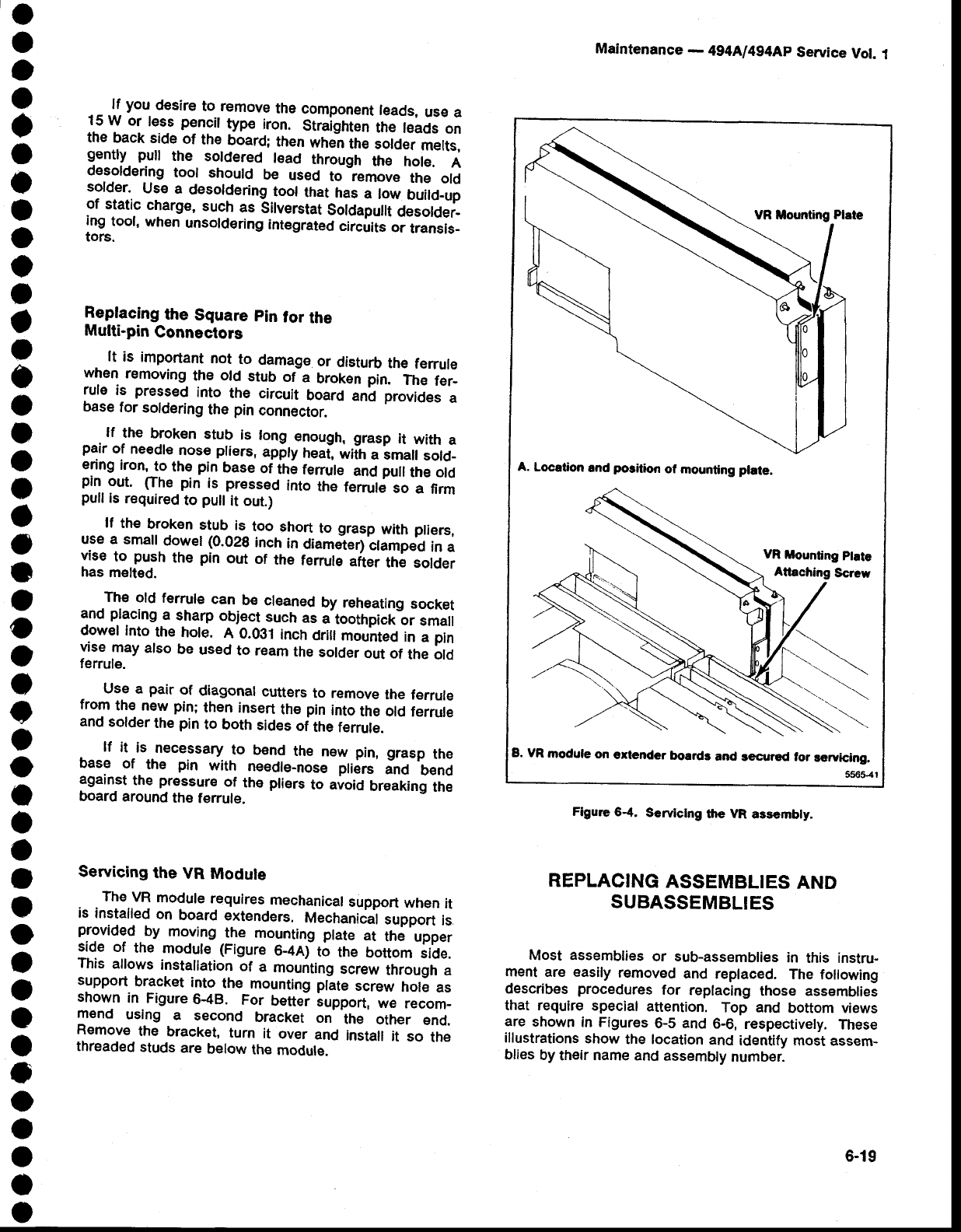

Servicing

the

VR

Module

The

VR

module

requires

mechanicat

support

when

it

is

installed

on

board

extenders.

Mechanical

support

is

provided

.

by

moving

the

mounting

plate

at

the

upper

:'.qe

of

the

modut€

(Figure

6_Anf

ti

the

bottom

sicte.

This

allows

installation

of

a

mounting

screw

through

a

support

bracket

into

the

mounting

plate

screw

hole

as

shown

in

Figure

6-48.

For

bettei

iupport,

we

recom-

mend

using

a

second

bracket

on

the

other

end.

Remove

the

bracket,

turn

it

over

and

install

it

so

the

threaded

studs

are

below

the

module.

Maintenance

-

494AJ494Ap

Service

Vot.

1

A.

Locetion

rnd

position

of

mounting plate.

VR

mounting

ptate

B, VR

module

on

€rtender

boards

and

secrred for

rervicing.

5565-41

Figure

6.4.

Serviclng

the VR

ass€mbly_

REPLACING

ASSEMBLIES

AND

SUBASSEMBLIES

Most assemblies

or sub-assemblies

in

this instru-

ment

are easily

removed

and

replaced.

The

following

describes

procedures

for

replacing

those assemblies

that require

special

attention.

Top

and

bottom views

are

shown

in Figures

6-5 and

6-6,

respectively.

These

illustrations

show

the location

and

identify

most assem-

blies

by

their

name

and

assembly

number.

6-19